Product Details

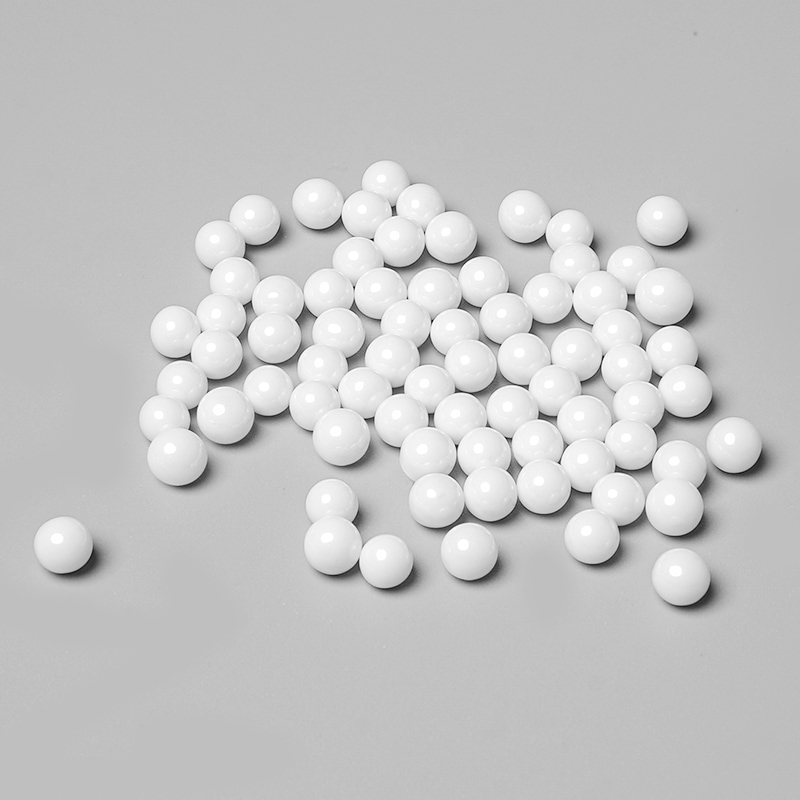

Ultra-wear-resistant Silicon Nitride Beads(Φ0.1-2.0)

• Chuangrui ultra-wear-resistant silicon nitride microbeads (φ 0.1-φ 2.0) adopt original extrusion molding technology and vacuum sintering technology, the density is ≥ 3.2g/cm, and its wear resistance is more than 10 times that of nano-zirconia beads and nearly 20 times that of high-purity zirconia beads, with excellent cost performance. The wear of silicon nitride microbeads in 24 hours is only one millionth, and there is basically no loss. Silicon nitride microbeads have very low grinding consumption, which reduces the wear of grinding media and the pollution to grinding materials, and is conducive to obtaining ultrafine powder with higher purity.

• Suitable for ultra-fine dispersion of high-end materials, especially for working conditions with high requirements on product purity and fineness.

1. Characteristics and advantages ofUltra-wear-resistant silicon nitride beads product materials

A. Ultra-fine Grain Size: Higher fineness of raw materials, lower wear rate, longer service life.

B. Ultra-high Density: Ultra-dense inner structure, strong impact resistance, no broken beads during use.

C. Uniform Bead Size Distribution: More stable grinding, results more sustainable productions.

D. Smooth Surface: Lower self-wear rate.

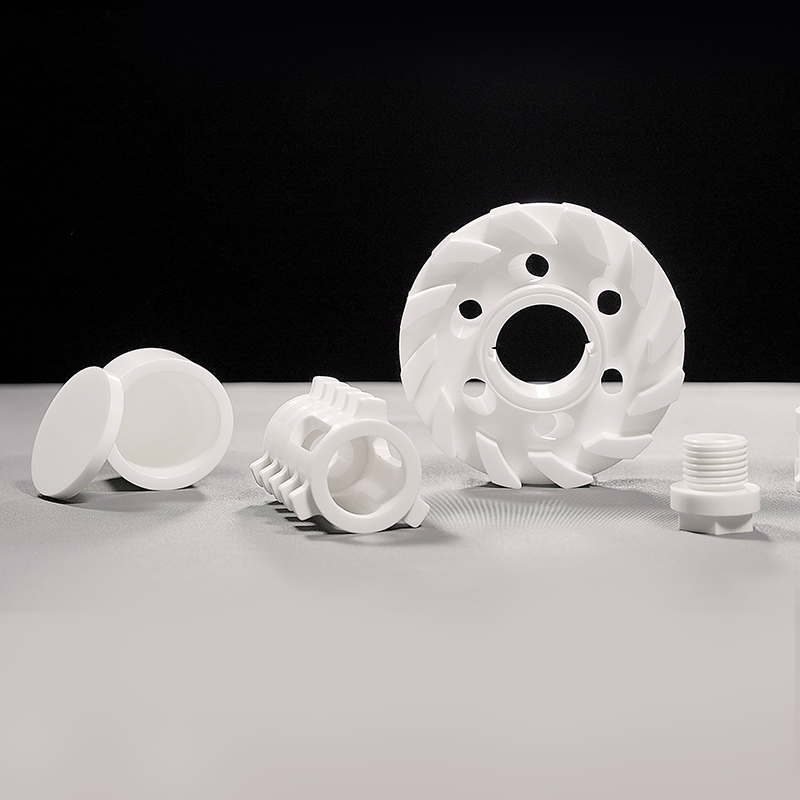

2. Production technology of silicon nitride beads

• By using the original extrusion molding process, and the bead is uniform and dense;

• By using Vacuum sintering process, and the density is greater than 3.2g/cm³;

• Super wear-resistant, more than 10 times more wear-resistant than zirconia beads, nearly 20 times more wearresistant than high-purity zirconia beads, highly cost-effective;

• Higher actual linear velocity, effectively improve the efficiency of ultra-fine dispersion by more than 30%;

• The density is only 53% of zirconia beads, which can reduce energy consumption and heat generation in the ultrafine process.

3. Applications

• Silicon Nitrde beads(Φ0.1-2.0)suitable for ultrafine dispersion of high-end materials, especially for working conditions with high requirements for product purity and fineness.

4. Comprehensive parameters

|

Index |

Unit |

Silicon Nitride Beads |

|

Bead Size Distribution |

mm |

Φ0.1-2.0 |

|

Density |

g/cm³ |

≥3.2 |

|

Crushing Strength |

Kgf |

≥50(Φ1.0mm) |

|

Sphericity |

Ds/Dl |

>0.97 |

|

Surface Self-wear Rate |

ppm/h |

<1.6 |

|

Internal Self-wear Rate |

ppm/h |

<1.5 |

|

Internal Porosity |

% |

<0.2 |

|

Size tolerance rate |

% |

≈0.5 |

5. Chuangrui Silicon nitride beads selection table

6. Silicon nitride beads production workshop