Product Details

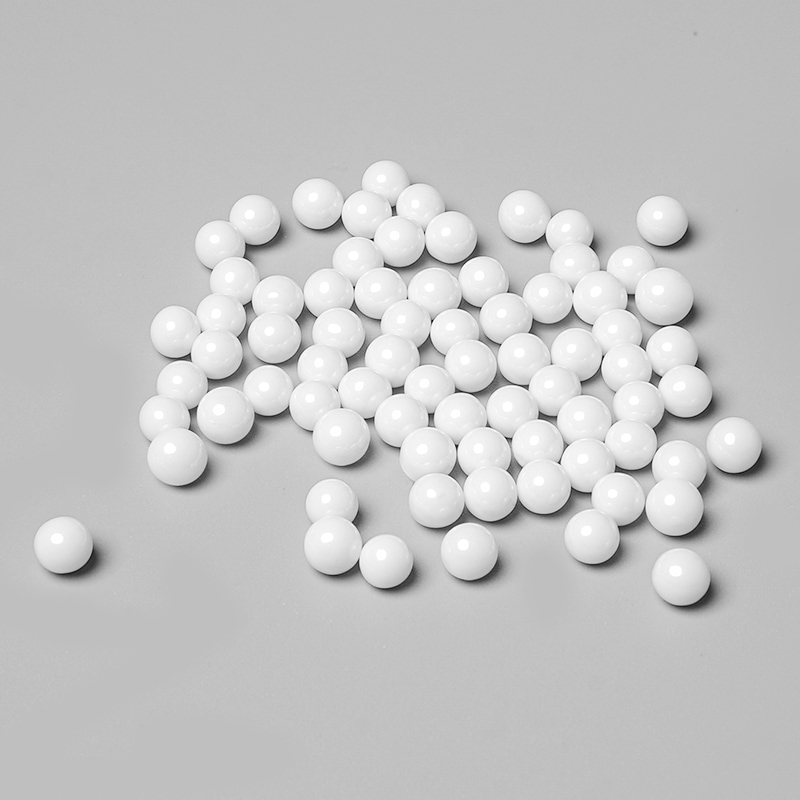

ZR95 Nano Zirconia Beads(Φ0.05-Φ2.0mm)

• ZR95 nano zirconia beads, also known as yttria-stabilized zirconia beads, are high-quality yttria-stabilized zirconia beads made of ultrafine crystallites, high purity and fineness raw materials by a unique extrusion molding process.

• ZR95 nano zirconia beads have the advantages of uniform particle size, ultra-high density and smooth surface, which makes the beads have extremely high wear resistance and impact resistance, which makes the grinding process more stable, the milled particle size more uniform and the service life longer. Ceramic materials have good biocompatibility, which avoids the pollution of grinding materials, ensures the purity of grinding materials to the greatest extent and ensures the high quality of products. It is especially suitable for grinding and dispersing materials with nanometer particle size range such as new energy, anode and cathode materials and electronic materials.

• We can customize non-standard grinding media, which can effectively help you reduce the use cost.

1. Characteristics and advantages of zirconia beads.

• Ultra-fine Grain Size: Higher fineness of raw materials, lower wear rate, longer service life.

• Ultra-high Density: Ultra-dense inner structure, strong impact resistance, no broken beads during use.

• Uniform Bead Size Distribution: More stable grinding, results more sustainable productions.

• Smooth Surface: Lower self-wear rate.

2. Product process of chuangrui zirconia beads.

• Using a unique extrusion molding process, the bead is uniform and dense;

• It is made of hydrothermal nano raw materials, low temperature sintering method, smooth surface, excellent wear resistance;

• Three-stage selection and secondary screening treatment are adopted to ensure the sphericity and beads size distribution;

• Ultra-high-speed pre-grinding treatment is adopted to ensure that there are no broken beads during use;

• It is suitable for ultra-fine dispersion of various materials and suitable for ultra-fine dispersion under high viscosity conditions.

3. Applications

• Suitable for ultrafine dispersion of various materials and for ultrafine dispersion under high viscosity conditions. Such as: Lithium iron phosphate cathode material, silicon carbon cathode, electronic materials, magnetic materials, carbon nanotubes, etc.

4. Comprehensive parameters

|

Index |

ZR95 Nano Zirconia Beads |

ZR95 High-purity Zirconia Beads |

|

(ZrO2)Zirconia Content |

94.5+0.2(%) |

94.5+0.5 (%) |

|

Density |

≥6.03g/cm³ |

≥6.0g/cm³ |

|

Pack Density |

3.75g/cm³ |

3.7g/cm³ |

|

Crushing Strength(Φ0.3mm) |

≥10Kgf |

≥9Kgf |

|

Sphericity |

>0.98Ds/Dl |

>0.95Ds/Dl |

|

Size tolerance rate |

≈0.5‰ |

≈1‰ |

|

Weared value |

?150ppm/h |

?200ppm/h |

|

Vickers Hardness |

≥1250HV |

≥1230HV |

|

Beads Size Range Available |

Φ0.05-Φ2.0mm |

Φ0.3-Φ5.0mm |

5. Chuangrui zirconia beads selection table

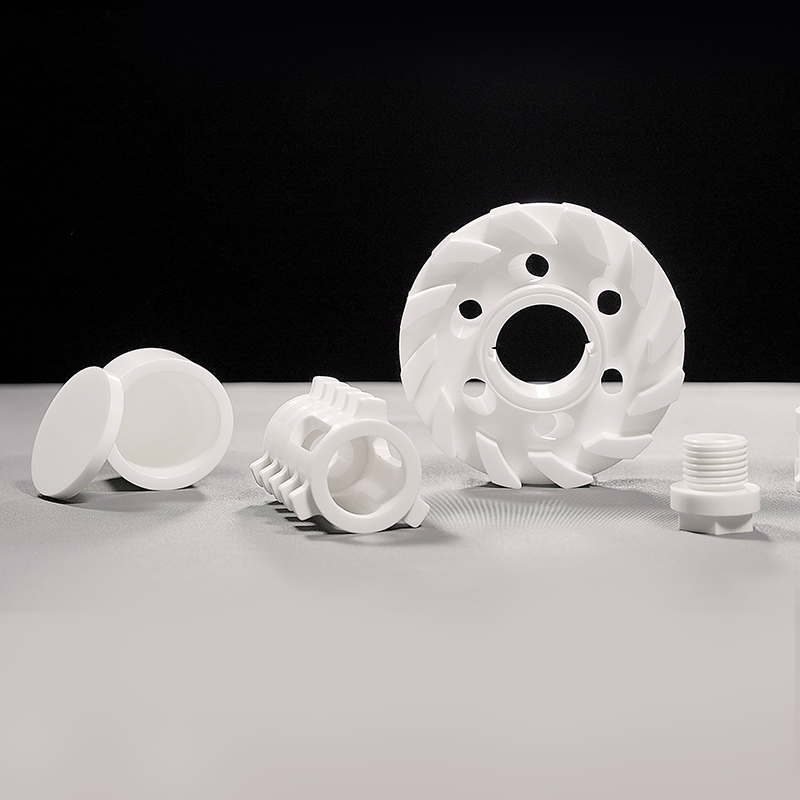

6. Zirconia beads production workshop